First, let’s make a brake.

Stock.

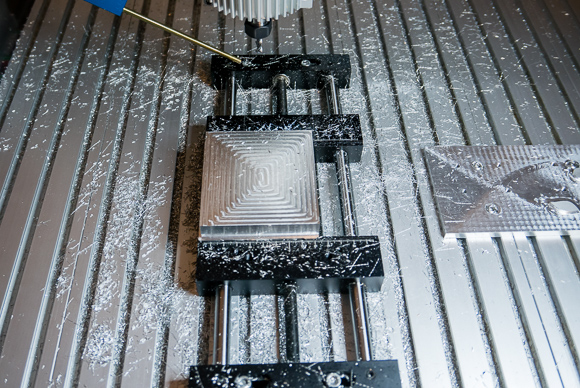

Fixture.

Dialed in.

Stock to size.

Flip, make pockets.

Pilot hole, flip, repeat. Finish on the drill press.

Profile.

Chamfer, flip, repeat.

Ready.

400 grit, 800 grit, finishing.

Complete brake assembly: fox + cord + bungee + accessory cord + tent stakes.

Fixed side. Protecting both the tree and the cords/slings

Adjustable side. Mezzo poldo for tightening (3:1 mechanical advantage).

Fox on.

Tent stakes pitched. Plus a couple of round gaskets in front of the brake to prevent metal to metal impact.

Trimmed handlebar plus grips, two belaying carabiners, cord and twin pulley (or golden heart according to Nelly).

Two clove hitches in the middle.

Pulley on. Plus backup. Everything is rated between 24 and 30kN (i.e. can lift a truck), but it doesn’t harm to have a backup.

Volunteers.

Wheeee…